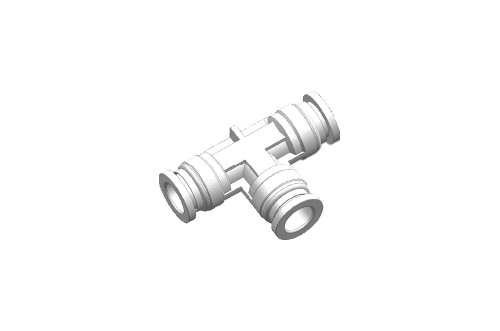

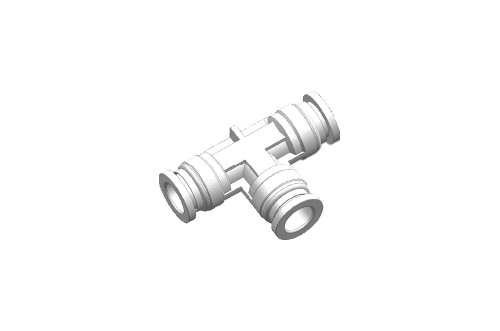

Stainless Steel Labor Saving Fittings - SSE T-Shaped Three-Way

Introduction

The new stainless steel pneumatic fittings are manufactured using premium 304 or 316 stainless steel and are entirely produced through powder metallurgy processes. Our company has independently developed a fully integrated powder metallurgy production line, encompassing injection molding, debinding, sintering, assembly, testing, and packaging. This streamlined production process ensures highly competitive pricing. The fittings feature a durable five-piece design, capable of maintaining stable performance under high-pressure conditions up to 40 kg. Each fitting undergoes stringent airtightness and leak testing before leaving the factory, guaranteeing reliable operation of the user's equipment.

Advantages

1. Compared to standard stainless steel fittings, it offers approximately 65% enhanced corrosion resistance, making it highly suitable for applications in the lithium battery industry.

2. Compared to traditional manufacturing processes, the product achieves a density of 8 g/cm³ and a hardness of 280 HV, delivering a more uniform and robust structure. The housing surface is free of burrs, and the inner wall is smooth, ensuring optimal airflow.

3. Compared to conventional stainless steel fittings on the market, it is lighter and more compact, saving approximately 30% of installation space and performing well in confined and complex working environments.

4. Compared to standard stainless steel fittings on the market, it is better suited for extreme and specialized operating conditions. The internal fluororubber seals are resistant to high temperatures, allowing operation at up to 250°C without leakage.

Online Inquiry